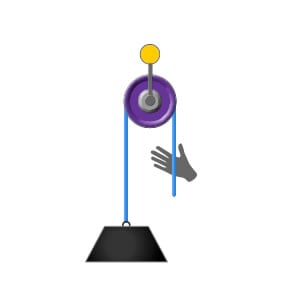

The 1:1 Redirect Pulley System

In the illustration to the right we have a rope attached to a load weighing 100kg. The rope has been passed through a pulley which

Please confirm you want to block this member.

You will no longer be able to:

Please note: This action will also remove this member from your connections and send a report to the site admin. Please allow a few minutes for this process to complete.